Valve Stations

Innovation built on strong roots

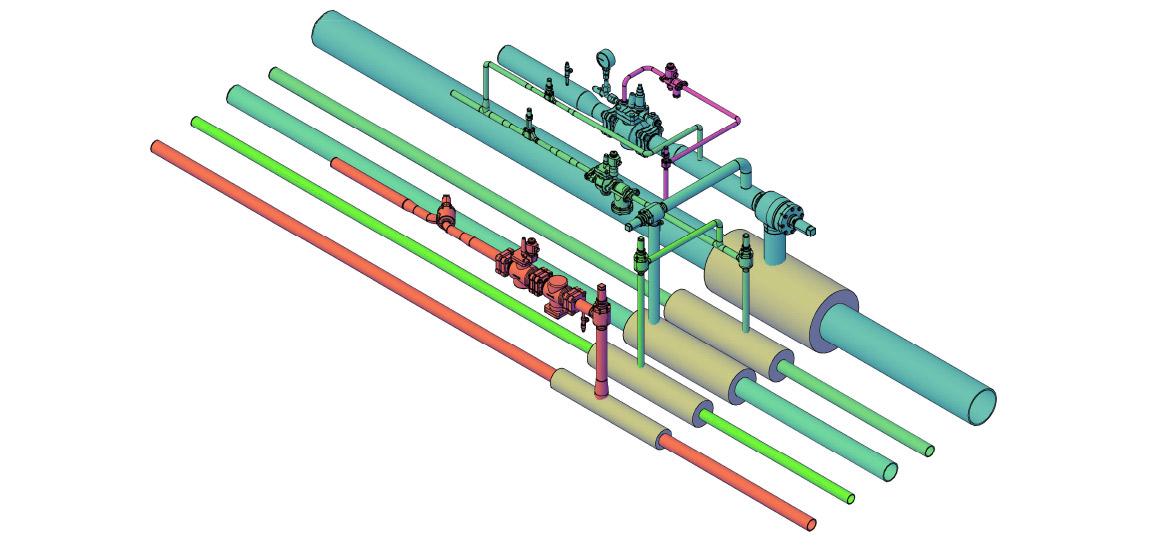

Our turnkey solutions for custom designed prefabricated valve/control stations means faster construction time and lower project costs

Through close coordination with our engineering team and the use of special software, we are able to design our valve stations with the necessary precision required to pre-fabricate them at our facility. This ensures that we maintain a controlled environment throughout the fabrication process and are able to deliver projects on time and within budget.

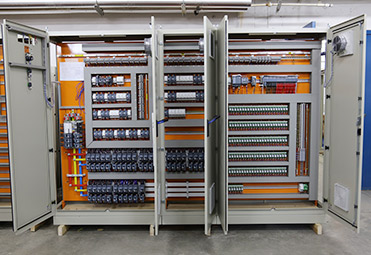

In-house Capabilities

PSI can comprehensively analyze your designs or create designs for you based on your process requirements. We are high pressure equipment manufacturer that employs advanced methods of design, including stress and fatigue analysis reports and finite element analysis if required.

Max. working pressure : 52 bar g (754 psig)

The external surface is zinc-TLP treated to provide corrosion protection according to ISO 14001-2015

Additional on-site corrosion protection is recommended.