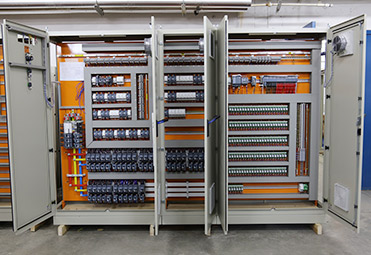

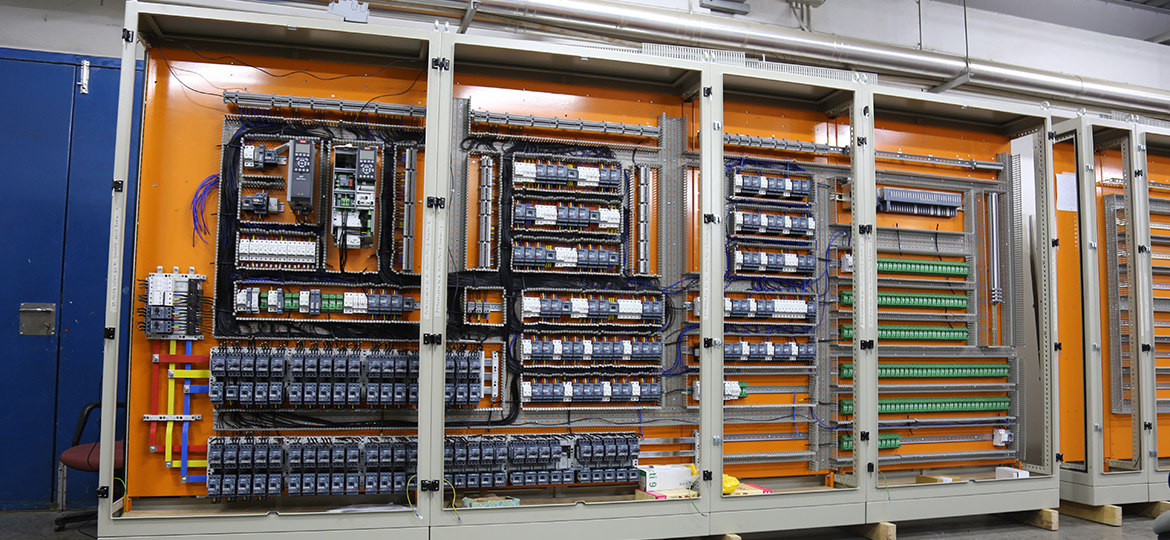

Main Distribution Boards (MDB)

Innovation built on strong roots

Designed to monitor and control the packaged equipment for your industrial applications requirement

An MDB is a panel or enclosure that houses the fuses, circuit breakers and ground leakage protection units, where the electrical energy that is used to distribute electrical power to numerous individual circuits or consumer points is taken in from the transformer or an upstream panel.

In-house Capabilities

PSI can comprehensively analyze your designs or create designs for you based on your process requirements. We are high pressure equipment manufacturer that employs advanced methods of design, including stress and fatigue analysis reports and finite element analysis if required.

PSI designs and manufactures application specific control panels that meet the appropriate IEC standards for every project. PSI electrical engineer staff can design simple alternating relay panels all the way up through custom industrial program logic controllers (PLC) and human machine interface (HMI) configurations. Every IEC listed control panel is designed with the end customer in mind to make operation and maintenance of the system as easy as possible and meet any specific requirements of the owner and maintenance staff.

The highest level of a site electrical layout that PSI offers, is the complete layout of all conduits (with sizing) and equipment on your site plan. With PSI's sister company ADEAREST, our team can offer a complete control building that is well designed to meet any site design needs.

PSI can offer design services and equipment to replace the old outdated (legacy) controllers with new modern industrial grade program logic controllers (PLC) and human machine interfaces (HMI). These upgrades can extend the life of the system while offering more flexibility along with new monitoring and SCADA options. PSI handles these control panel repair/retrofit projects on a case by case bases to make sure that the end user gets the best possible outcome.

PSI provides project specific programming for every control panel manufactured, that includes a program logic controller (PLC) and/or human machine interface (HMI). PSI can use a customer's provided program and "load" it on the PLC and/or HMI prior to delivery to the site. In addition, PSI also offers custom programming to meet any requirements for a given pumping scenario. Our PLC/HMI programming always keeps ease of operation in mind to make sure that the end user/operator feels comfortable with complete pumping system.