Pressure Vessels

Innovation built on strong roots

Highly-engineered, intricate vessels that are safe and reliable.

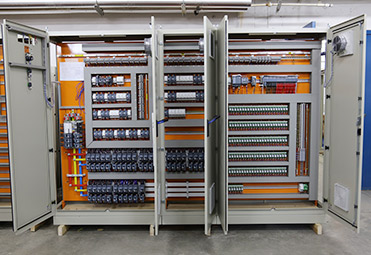

PSI is specialized in the engineering, design and manufacturing of heavy duty pressure vessels, including piping systems, assemblies and valves. Our pressure vessels are manufactured using steel or stainless steel, with wall thicknesses of up to 50mm. Furthermore, Our team is also able to manufacture pressure vessel of various sizes for different applications, such as ammonia separators, boilers, storage tanks, LPG tanks, as well as being able to customize a vessel to your specific requirements. We are ASME certified, but are also able to design pressure equipment to comply with the local standards of your region.

Steps to Fabricate a Pressure Vessel

To help you understand the process easier, the fabrication process has been divided into steps. Before the fabrication process is begun, a few important design steps must be performed. These are given below in brief.

List the Design Criteria

This is where all the technical specifications and requirements are taken from the client. The design criteria will include aspects such as the shape of the vessel, and details such as material of construction, length, diameter, internal pressure & temperature, etc.

Perform Mechanical Strength Calculations:

With pressure vessel design software, the mechanical calculations are performed to determine the required material thicknesses and weld sizes.

Generate Fabrication Drawings:

Fabrication drawings are produced based on the design criteria and mechanical calculations with software such as AutoCAD. These drawings can be produced in 2D or 3D, but usually 2D will suffice.

Cut and Roll the plate into cylinder:

A large amount of plate is cut into the required width and length for the vessel shells. A specialized cutting torch is used to cut the steel. A variety of torches can be used depending on material and required edge quality. Bevels are usually cut on edges at this time. The plate is then rolled into cylinders of required diameter. Usually the plate is rolled cold, but can be done hot in order to use plate rolls of a smaller capacity.

Pressure Vessel Cylinders and Heads

Fitting & Welding the Pressure Vessel Cylinders is usually performed with submerged arc welding.

Various cutting torches can be used to cut the plate for the pressure vessel head. Then the pressure vessel heads are formed using a variety of techniques, usually flanging and spinning or press forming is used.

Fit & Weld Heads to Pressure Vessel Shell

Usually performed with submerged arc welding.

Install Nozzles

Holes need to be cut into the steel plate for the required vessel nozzles. This is usually performed with a manual plasma-arc or oxyacetylene cutting torch.Final edge preparationis performed by manual grinding.

Nozzles and reinforcement pads are welded in usually using a manual wire welding technique.

In-house Capabilities

PSI can comprehensively analyze your designs or create designs for you based on your process requirements. We are high pressure equipment manufacturer that employs advanced methods of design, including stress and fatigue analysis reports and finite element analysis if required.

With our experience, we can quickly develop procedures for joining your unique material selection if we do not already have procedures developed for the material you request.